In recent years, charcoal extract fabric has gained significant attention for its unique properties and eco-friendly nature. This innovative material not only offers comfort and durability but also incorporates the benefits of activated charcoal, commonly used in clothing, home textiles, and various fashion accessories.

The Production Process of Charcoal Extract Fabric

- Sourcing Raw Materials

The production of charcoal extract fabric begins with sourcing high-quality raw materials. The primary materials include natural fibers such as cotton, bamboo, or hemp. These fibers are selected for their comfort and breathability, which enhance the overall qualities of the final fabric.

- Activated Charcoal Preparation

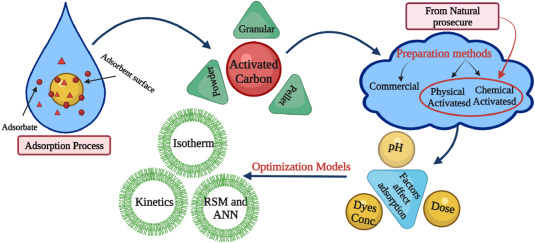

This is typically done by carbonizing organic materials like coconut shells, wood, or bamboo at high temperatures in a low-oxygen environment. This process removes moisture and volatile compounds, resulting in a porous structure that enhances the charcoal’s absorption capabilities.

- Fiber Blending

Once the activated charcoal is prepared, it is blended with the chosen natural fibers. This can be achieved through several methods, including spinning or mixing during the fiber preparation stage. The ratio of charcoal to fiber can vary, but a common range is between 5% to 20% charcoal content, depending on the desired properties of the fabric.

- Spinning the Yarn

After blending, the mixture is spun into yarn. This process involves twisting the fibers together to create a strong and cohesive strand. The spinning process can influence the fabric’s texture and strength, making it crucial for achieving the desired outcome.

- Weaving or Knitting

The spun yarn is then woven or knitted into fabric. This stage is where the unique qualities of the charcoal extract fabric begin to emerge, as the activated charcoal gets integrated into the structure of the textile.

- Finishing Treatments

To enhance the fabric’s performance, several finishing treatments may be applied. This can include processes like dyeing, softening, and antimicrobial treatments. These finishing steps not only improve the appearance and feel of the fabric but also maximize its functional benefits.

Charcoal extract fabric represents a significant advancement in textile technology, combining the benefits of activated charcoal with the comfort of natural fibers. Its unique properties make it an excellent choice for a wide range of applications, from fashion to home textiles.

Learn more: http://www.springtextile.com Or Spring Hometextile video channel: www.youtube.com/channel/UCMCz-yKQMYxA1e2Uscw5PHw Also can contact Tina at: [email protected]